Hydraulic Test Rigs

Test | Measure | Record | Certify

Conduct rigorous component and equipment testing in-house to save time and reduce costs. Test rigs come in all shapes, sizes, and degrees of complexity, able to perform a single or multiple tests, to meet quality control objectives.

Test a range of conditions, such as high-temperature and high-pressure, to put part quality through its paces. Hydraulic test rigs are custom designed and built for individual applications. Features include test chambers, a range of outlet and return ports (allow testing of different components and equipment), hydraulic power unit, motor, heater, cooling, and filtration. Monitor testing via digital readouts and collect data via external test connections for remote readings.

Test rigs are designed to accurately test, measure and certify components and equipment. Fault finding is a key concern to avoid the cost and damage of a quality issue. Take control of quality processes in-house with a hydraulic test rig.

Multi-Function Hydraulic Test Rig

Drive: Electric

Flow Rate: 60 LPM

Pressure: 350 Bar

Tank: Includes scavenge system

Enclosure: Stainless steel test area and panels

Key Points

- Multiple outlet and return ports test a range of components

- Cylinders and hydraulic motors allow visual monitoring of test parts driving components

- Scavenge system on tank return guarantees high oil cleanliness standards, even when testing potentially contaminated parts for repair

- Electronically controlled main pump flow

- 350 Bar, 5 LPM pilot control

- Full electronic control interface

- 6” Visual pressure gauges

- Electronic display flow meters

- Manual remote pressure control

- Integral lower drip tray.

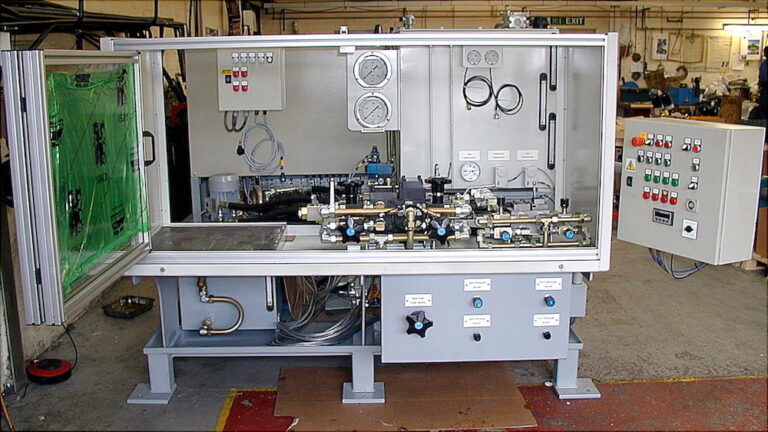

Cetop 3, 5, 7 and 8 Hydraulic Test Rig

Drive: Electric

Motor: 30 kW motor

Flow Rate: 80 LPM

Pressure: 220 Bar

Pump Type: Manually controlled pump flow and pressure

Enclosure: Includes bi-folding access door with safety switch for operator safety

Key Points

- 50 Bar, 35 LPM pilot control

- Full electronic control interface

- 6” Visual pressure gauges

- Electronic display flow meter

- Scavenge system on tank return to guarantee oil cleanliness including potentially contaminated parts for repairCeto

- p 3,5, 7 & 8 interfaces hard piped for valve testing

- Additional outlet and return ports to allow a wide range of components to be tested

- External pump skid with air blast cooler remotely mounted in pump room ensures minimum low-noise operation

- Immersion heater

- Pressure and return filters.

Aerospace Component Test Rig

Drive: Electric

Motor: 15 kW main motor pump unit

Flow Rate: 30 LPM

Pressure: 320 Bar

Tank: Fully integrated

Enclosure: Stainless steel panelling with front opening access doors

Key Points

- 55 LPM low pressure recirculation and cooling motor pump unit

- Plate-type water cooler

- 3 Micron pressure and return line filters

- Integral design with tank connections available externally

- Rear-mounted connection bulkhead

- Louvered lower compartment with motor pump units fitted inside

- Integral drip tray

- Pressure control setting external pressure shown on 4” calibrated pressure gauge

- Compact design.

Simple Hydraulic Pressure Test Rig

Drive: Electric

Motor: 5.5 kW

Flow Rate: 4.8 LPM

Pressure: 350 Bar

Key Points

- Outlet ball valve

- Return line check valve

- 10 Micron pressure filter

- 6” Diameter pressure gauge

- Ergonomic tri-lobe pressure adjustment handle

- Cooler matrix above motor fan utilises air flow from motor fan

- Combined return line filter, filler and air breather

- High temperature thermostat

- Low-level float switch

- Low cost.