Industrial Hydraulic Power Units

Any Size | Any Flow Rate | Any Pressure | Always Efficient

Commonly used to hydraulically actuate precise power and control over heavy-duty and high-volume operations such as furnace control, machine tool clamping, steel processing, and a range of auxiliary functions. Efficiency and simplicity in design ensures safe and cost-effective operation, from largescale infrastructure projects and mobile operations to light- and heavy-duty processing.

Large hydraulic systems – over 100LPM

The heaviest-duty industrial applications are almost solely reliant on hydraulic systems to get the job done. Andrews Hydraulics systems are proven to be reliable in the toughest environments, from quarries to foundries, delivering flow rates of up to 800LPM and beyond.

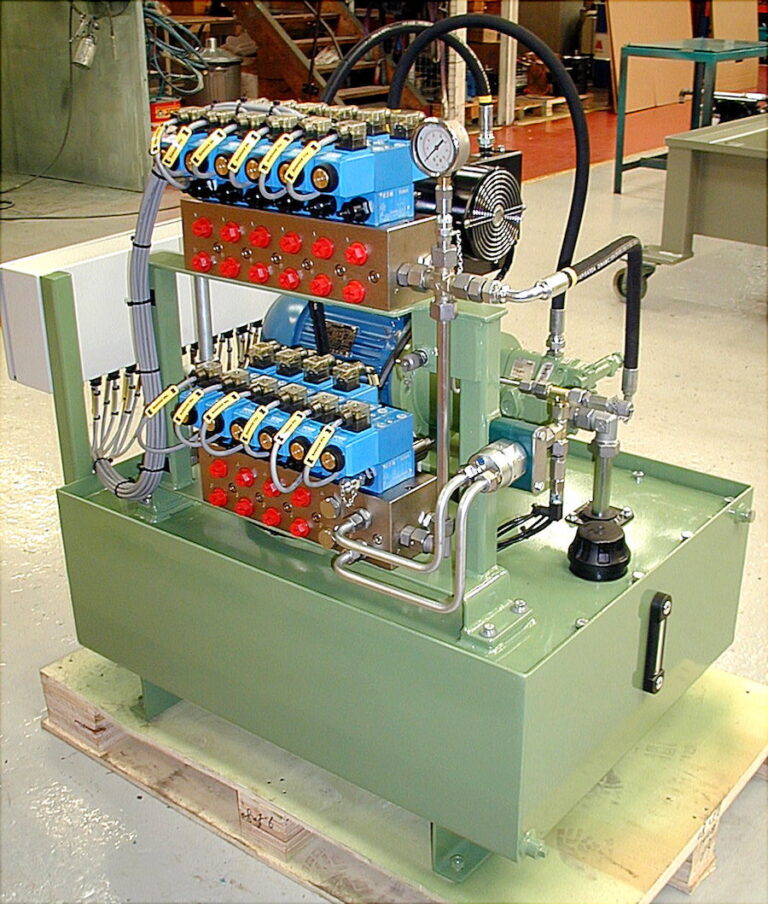

Medium hydraulic systems – up to 100LPM

Medium output hydraulic systems or HPUs flow up to 100LPM with a pressure range to suit individual applications. Modular and self-contained fluid power design is highly adaptable yet simple to maintain.

Small hydraulic systems – up to 30LPM

Also known as micro HPUs, small hydraulic systems flow up to 30LPM, achieving pressures up to 250bar. Ideal to meet time-critical projects, often performing a range of functions, providing a highly cost-effective solution.

Biomass Push Floor Control

Large Hydraulic System

Drive: Triple 55kw motor

Flow Rate: 144 LPM

Pressure: 200 Bar

Pump Type: Pressure compensated

Tank: 1500 Litre

Enclosure: 100% Bund

Key Points

- Integral pump unload through load sense port

- Proportional valve control to actuators

- Recirculating screw pump passing oil through an air blast cooler (external mount) and return to tank via a 10 micron filter

- Anti-vibration electric motor mount assembly

- Large capacity breather with integral condition indicator

- Replaceable element.

Furnace Control Power Unit

Large Hydraulic System

Drive: Electric

Motor: 50HP NEMA framed motor drive (U.S. end user)

Flow Rate: 100 LPM

Pressure: 140 Bar

Pump Type: Pressure compensated

Tank: 1500 Litre divided by internal baffle

Enclosure: Robust lifting frame

Key Points

- Logic element control valve assembly for large bore single acting cylinder application

- Ancillary valve assembly supports function controls

- Proportional valve with integral electronics and feedback

- Recirculating pump unit passing oil through 10 micron return line filter

- Plate type oil cooler connected to factory water system

- Emergency ball valves with flow control valves attached

- Duplex main return line filter

- Capacitive level sensor to signal oil level back to PLC

- Lower motor mount forms integral drip tray.

Steel Processing Power Pack

Large Hydraulic Power Unit

Drive: Electric

Motor: 2 x 75kw 6 Pole drive motors

Flow Rate: 216 LPM

Pressure: 210 Bar

Pump Type: Pressure compensated pumps with low flow bearing flushing pumps fitted

Tank: 2500 Litre stainless steel tank

Enclosure: Integral Bund

Key Points

- Water glycol application

- Pressure filters and duplex return line filters

- Large capacity plate cooler

- Separate manifolds with accumulators

- Electric parts wired to common junction box

- Integral lifting points

- Recirculating screw pump

- Welded steel pipe.

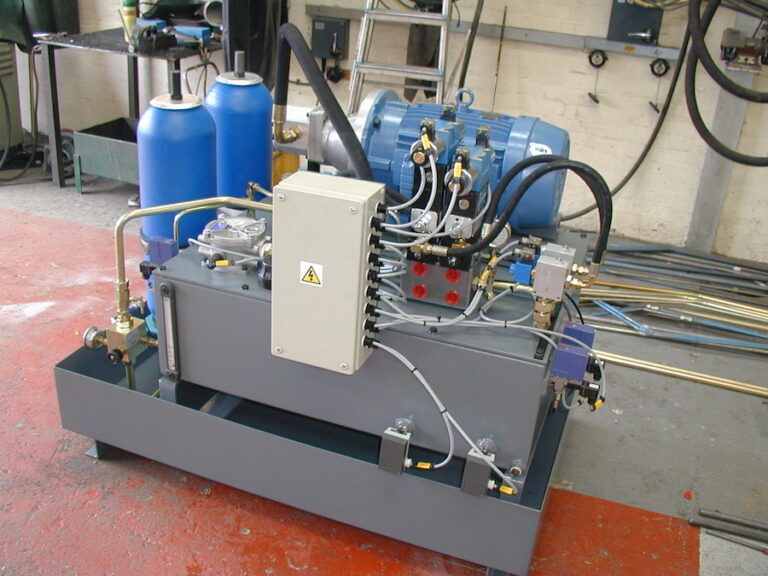

Machine Tool Clamping Power Unit

Small Hydraulic System

Drive: Electric motor

Tank: Small semi-static

Pump: Pressure compensated

Enclosure: Mounting points at tank feet

Key Points

Simple system for machine tool clamping

Low flow pressure compensated pump runs continuously with minimal heat generation

Case drain cooler

Standard solenoid valves and modules

10 Micron return line filter.