ICE Power Packs

Any Size | Any Flow Rate | Any Pressure | Always Efficient

Operating in remote locations requires an off-grid power source. ICE power packs (internal combustion engine) are usually diesel-powered units supplying energy for a hydraulic system. Andrews Hydraulics design and build custom ICE power packs to meet project-specific parameters, supplied worldwide.

- Remote power source

- Reliable in tough conditions

- Simple to transport

- Low-noise exhaust systems

- Modular or self-contained

- Spares supply.

ICE power packs are designed as modular or self-contained systems. Options include fitting to a robust lifting frame or safely housing a complete assembly within a shipping container for logistical simplicity. Appropriate cooling systems are fitted to suit intended operating conditions, specified to limit temperatures in potentially extreme environments. Sound and air pollution are limited by insulation, anti-vibration fittings, and low-noise primary and secondary exhaust systems.

Vibrating Piling Power Unit

Drive: Diesel engine driven pump unit

Flow Rate: 180 LPM and 90 LPM

Pressure: 280 Bar and 125 Bar

Pump Type: 2 x main pump / 3 x auxiliary pumps

Tank: Integrated fluid and fuel tanks

Enclosure: Robust lifting frame with removable panels and weld mesh

Key Points

- Diesel ICE powered system

- Fully integral unit

- Two main hydraulic pumps produce 180 LPM and 90 LPM

- Three smaller pumps for engine fan drive, lubrication and pilot control

- Hydraulic oil tank and diesel fuel tank contained within lower box section of lifting frame

- Electrical control system, utilising can-bus control to integrate with customer machine

- Pumps feature proportional flow control and pressure control

- Air blast cooler fitted for temperature limitation in extreme environments

- Pressure and return line filters (optimum fluid cleanliness)

- Centralised outlet bulkhead (simple connection to pipework)

- Pressure transducers and electronic flow meters

- Controls displayed on HMI screen, replicated in control room.

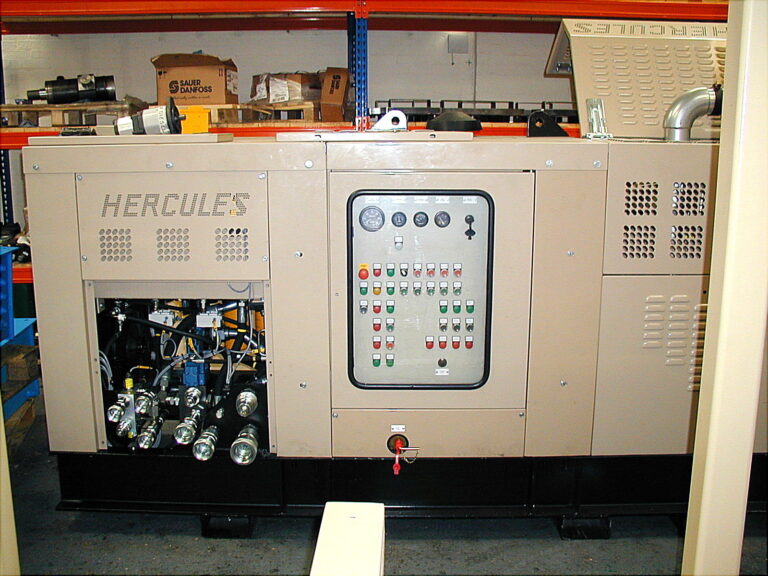

Shredder Power Unit

Drive: 300 kW Diesel engine

Motor: 2 variable-speed hydraulic motors

Flow Rate: 760 LPM

Pressure: 350 Bar

Pump Type: PTO for outlet conveyor control

Tank: Oil and fuel tanks accessible within enclosure

Enclosure: 20-foot soundproofed and insulated shipping container

Key Points

- Full electrical control, including remote operator station

- Air blast cooler fitted for oil temperature control

- Return line filters for optimum fluid cleanliness

- Centralised outlet bulkhead for simple connection to machine pipework.

Piling Crusher Power Unit

Drive: Diesel engine

Flow Rate: 150 LPM

Pressure: 300 Bar

Tank: Fully integrated oil and fuel tanks

Enclosure: Robust lifting frame weld mesh sheet

Key Points

- Integrated electrical control system

- Hydraulically actuated hose reels

- Hoses connect to crushing head fitted to mobile plant

- Remote control operated solenoid valves allow operator to access control functions via handheld interface panel

- Air blast coolers fitted for temperature limitation in extreme environments.